The CAD / CAM nesting software

Welcome to CutExpert® LITE world

Over the past few years, the technology associated with sheet metal cutting has grown considerably.

We have gone from doing a lot of work manually to the realization of each single part through the use of machines, thus significantly reducing execution times.

ts from simple carpentry to the creation of complex shapes for design accessories.

The solution proposed by Eurosoft is the result of more than 30 years experience, acquired in the field, in close collaboration with operator specialized on metal cutting, drawing from them the useful tricks to make the application fast and effective.

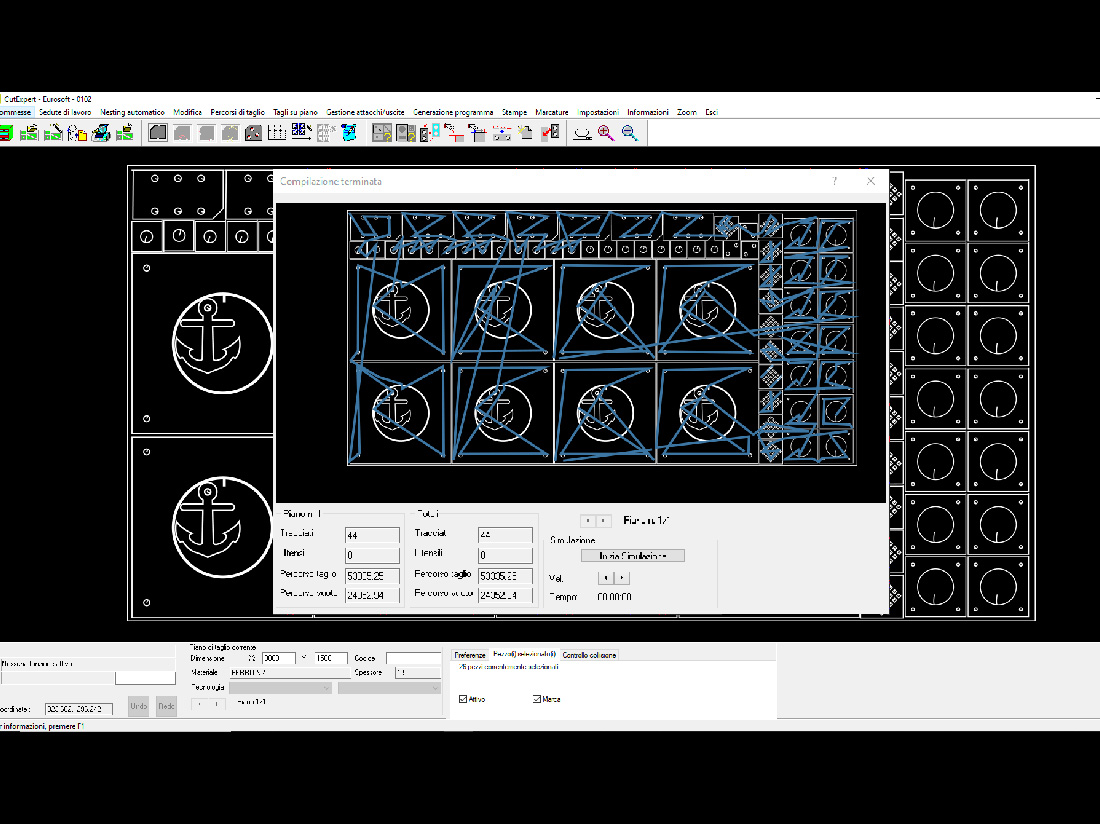

The system perfectly communicates with sheet metal cutting machines such as laser, plasma (even 5 axes), oxy-cut and water jet.

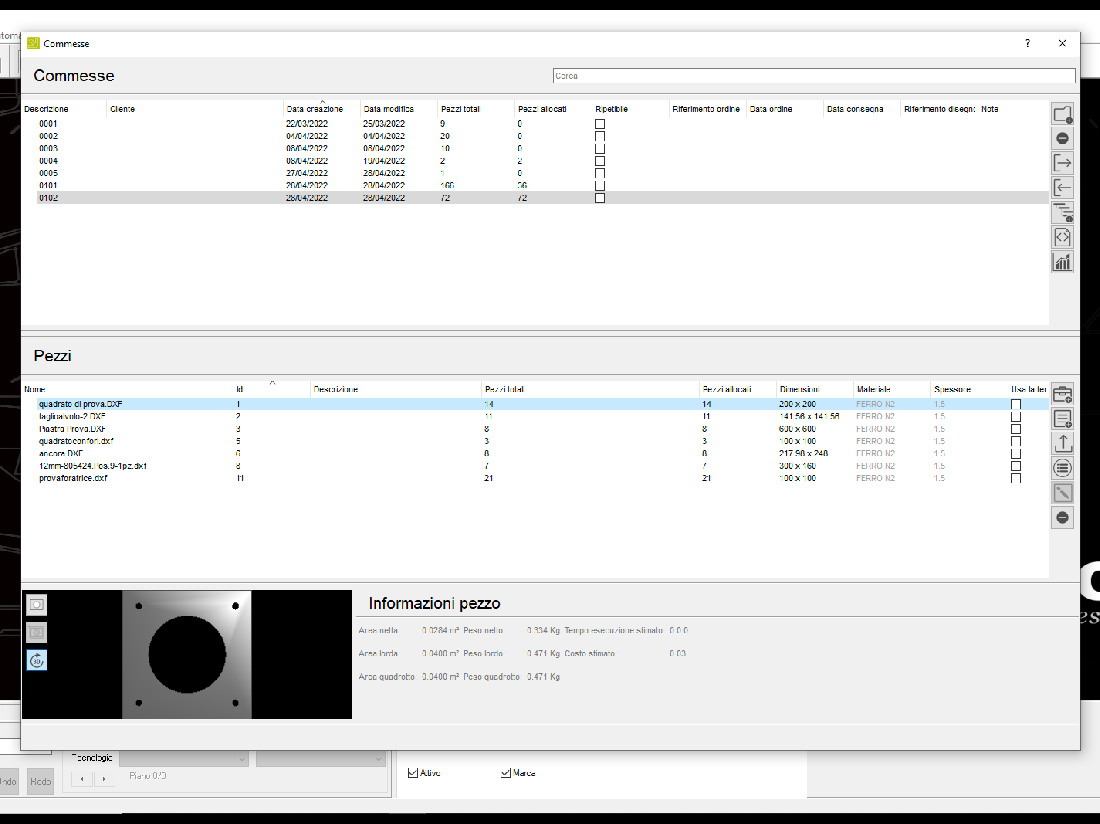

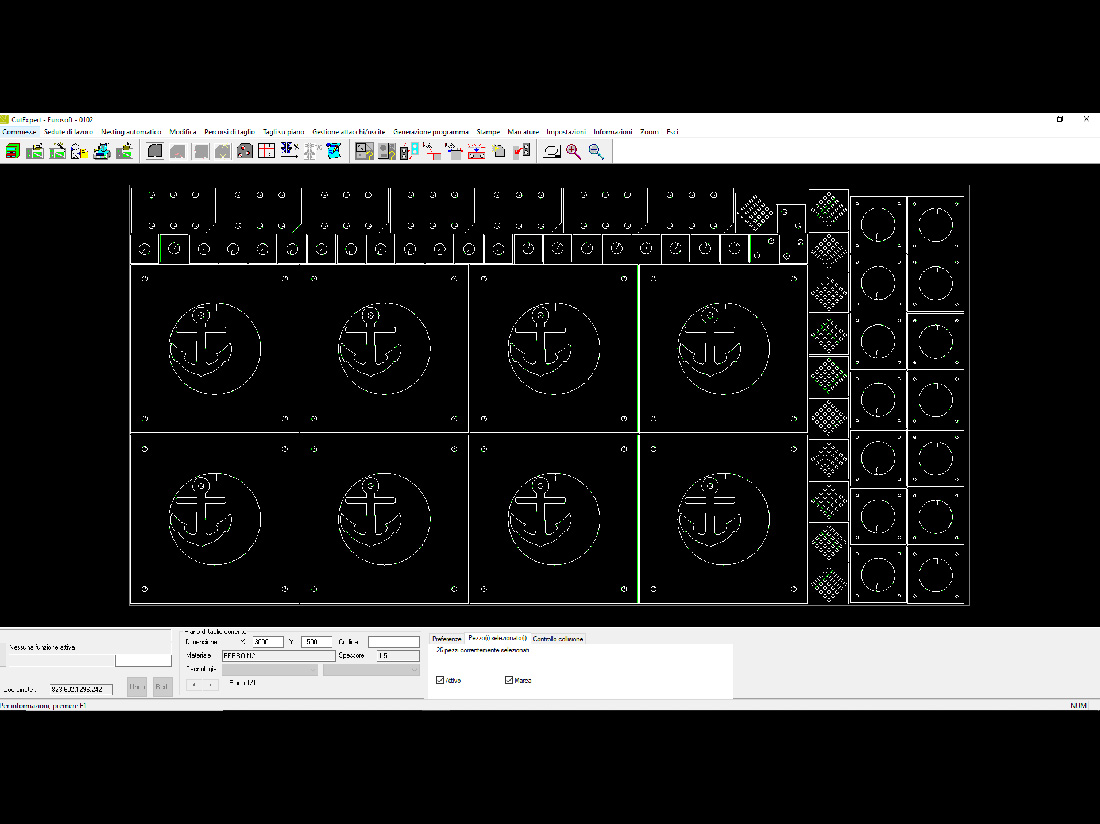

CutExpert® LITE suite allows, in a few simple steps, to realized every parts quickly, minimizing the scrap.

Our module is perfectly integrated with the other Eurosoft software such as

Mosaico (intelligent automatic nesting that allows a further reduction of scraps up to 10%) and

Revolution 4.0 (the software that allows to extract all the informations for Industry 4.0).