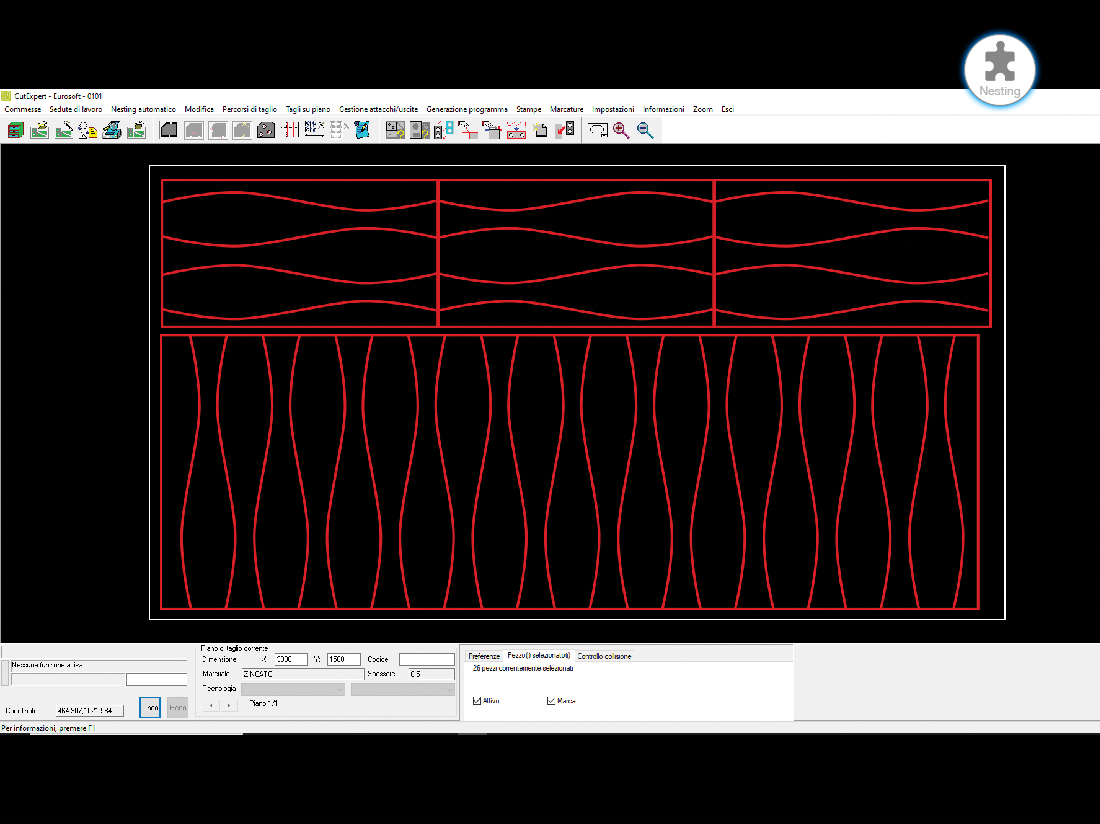

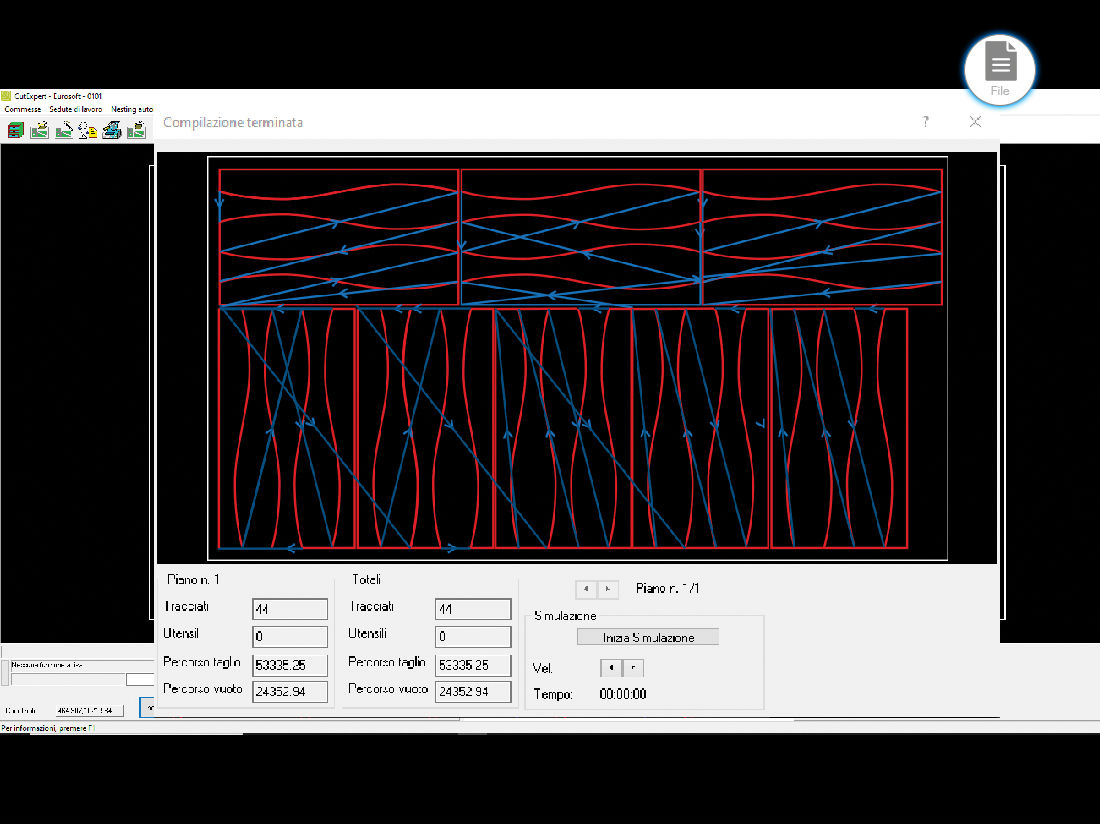

The CAD / CAM nesting software

Welcome to CutExpert HVAC world

CutExpert® HVAC is the most appropriate software for those who realizes aeraulics, aspiration and thermal insulation systems.

Over the past years, the technology has grown considerably, in fact, we have gone from tracing the shapes by hand to development of entire systems in few simple steps, significantly reducing execution times.

Our automatic development module is the result of more than 30 years experience, acquired in the field, in close collaboration with operator specialized on HVAC sector, drawing from them the useful tricks to make the application fast and effective.

Eurosoft, both with continues growth and optimal investment strategies, was able to identifying customers needs and the innovations to focus on, in order to improve the work quality and reduce production times.

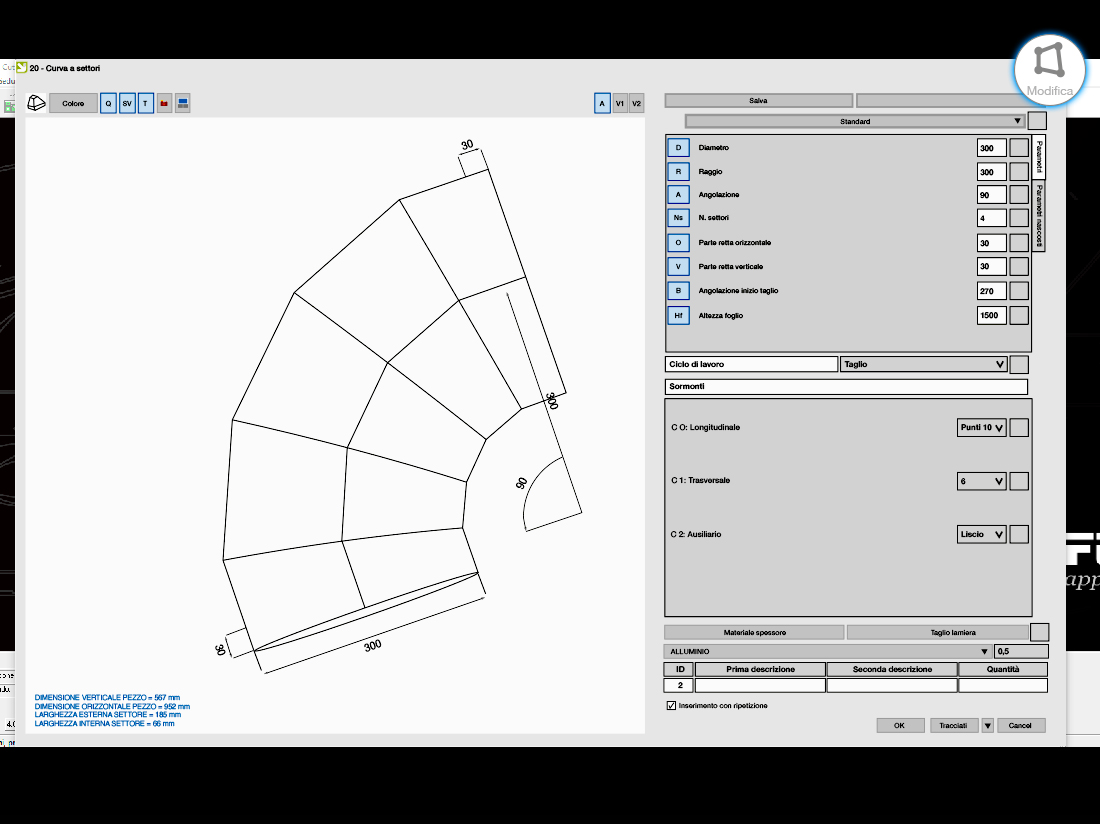

CutExpert® HVAC suite allows, in a few simple steps, to realized every parts of a system, overcoming the difficulties that can be found and the errors that can be incurred using a traditional 3D. In fact, our software, based on variational parametric, allows, by entering only a few parameters, to see immediately every modification on 3D model, updating the view and the relative 2D drawing.

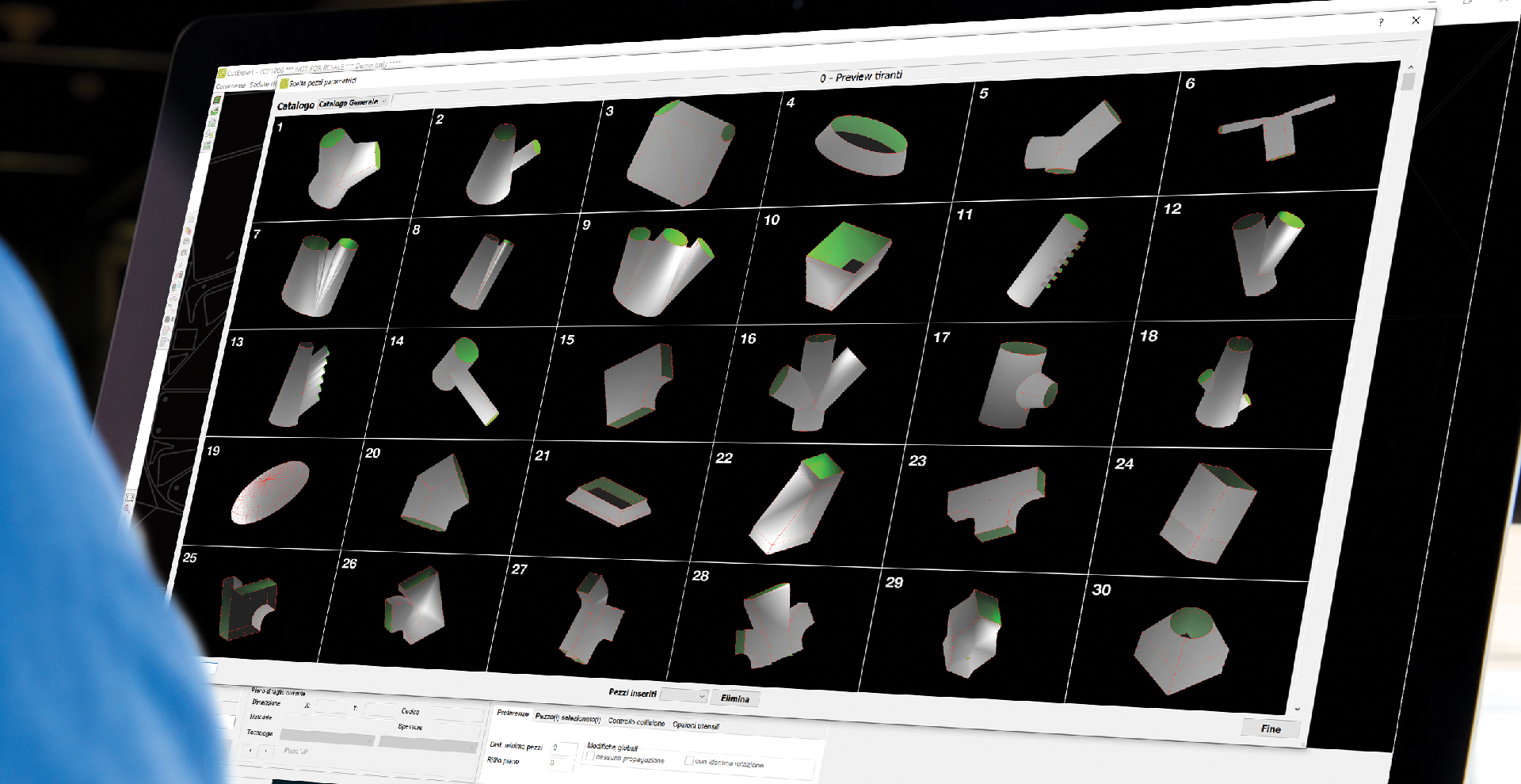

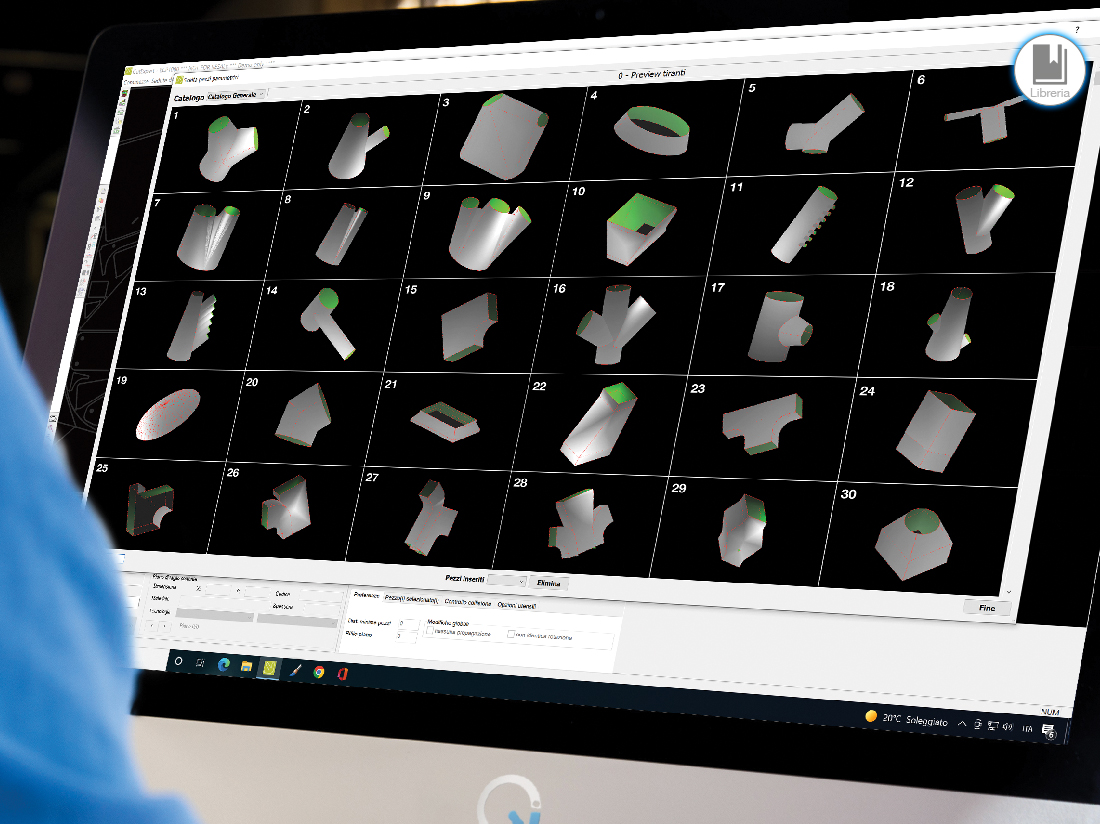

CutExpert® HVAC contains a library with over 180 parametric parts, that allow you to create any type of aeraulics, aspiration and thermal insulation systems.

The flexibility and the total customization of the parametric parts, integrated as a supply in the suite CutExpert® HVAC allows to use the widest graphic package on the market.

The continuous study of new technologies allows us to create customized parts in a very short time.

The simplicity of the software makes possible a perfect customization of the part through the insertion of a few parameters, that can be configured directly by the user in a very easy way.