The most powerful CutExpert® yet:

- New and customizable design

- more performing database

- Unprecedented speed

Do you want to try the new version of the software?

Book an appointment with one of our technicians

> Hilights | > Video Tutorial | > Caratteristiques

born from 30 years of experience

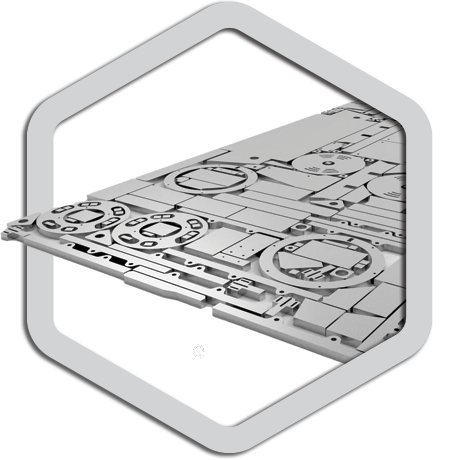

CutExpert is an advanced and complete solution for cutting management and optimization, designed to meet the needs of companies operating in the metalworking sector.

With CutExpert you can optimize your work processes, reducing material waste and increasing production efficiency, with its advanced features, optimizing the positioning of the pieces to be cut and minimizing losses with consequent savings on material costs and increase in your profitability. Thanks to its powerful features, you can plan and manage precisely and

fast cutting of sheets, tubes and metal profiles, obtaining high quality results and maximizing the yield of your materials.

The software offers a wide range of tools and customization options, allowing you to tailor the solution to your specific needs. You can define cutting parameters, configure processing sequences, manage production priorities and monitor the status of your orders in real time.

Choosing CutExpert means investing in reliable, intuitive and high-performance software, which will help you improve your productivity, optimize your cutting processes and obtain high-quality results.

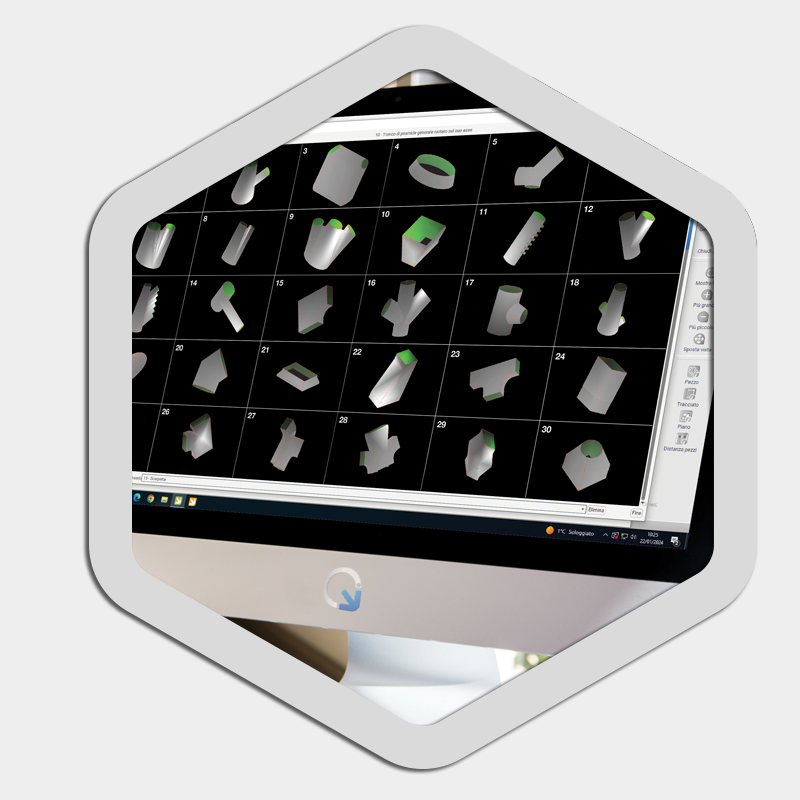

LITE or HVAC

CutExpert®LITE allows you, in a few simple steps, and by entering a few parameters, to create all the items useful for your work simply and quickly, reducing sheet metal waste to a minimum. With the HVAC version of CutExpert® it is possible to create all the components of a system, overcoming the difficulties that may be encountered and the errors that may be encountered using traditional 3D. In fact, the system, based on parametric variational, allows you to immediately distinguish what is modified in 3D development, directly updating the view and also the related transformation in 2D. CutExpert® HVAC includes a library made up of more than 180 parametric figures that allow you to create any type of aeraulics, extraction and insulation system. Parameterization extremely flexible of each shape, combined with the vastness of the library, makes CutExpert® the most versatile HVAC program on the market.

Hilights

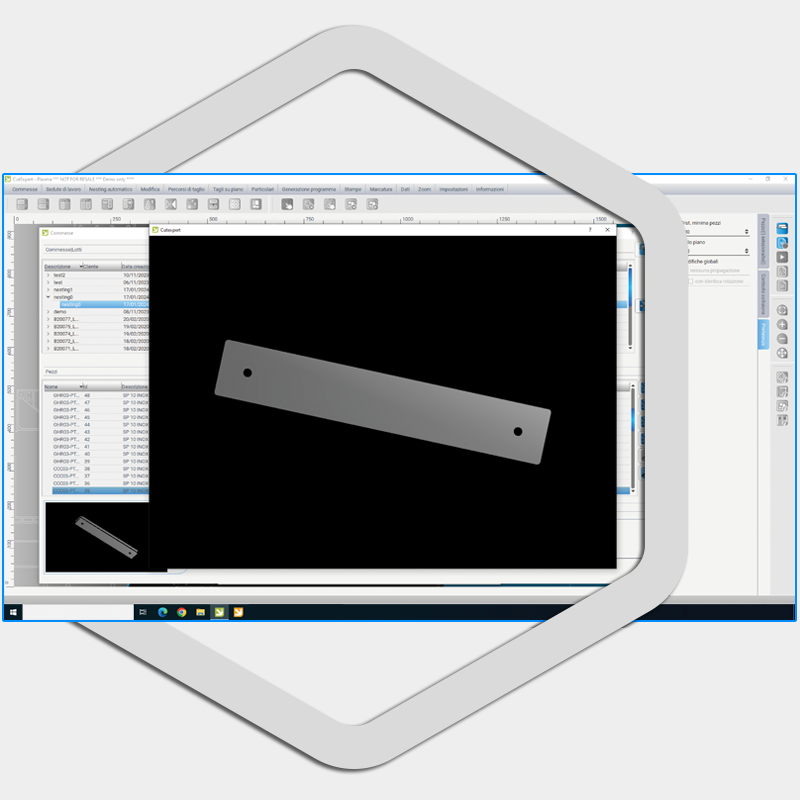

Order management

Cutexpert manages orders and processing batches. Pieces of different material/thickness can be loaded, modifying the quantities, description and other auxiliary parameters, both from the HVAC catalog and from files.

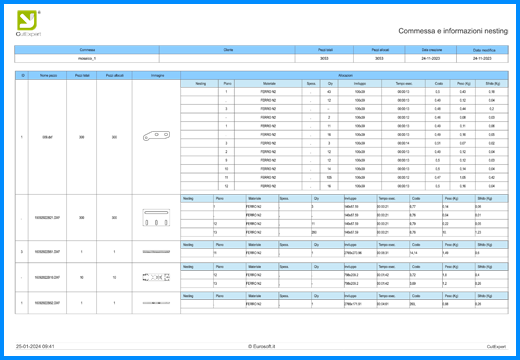

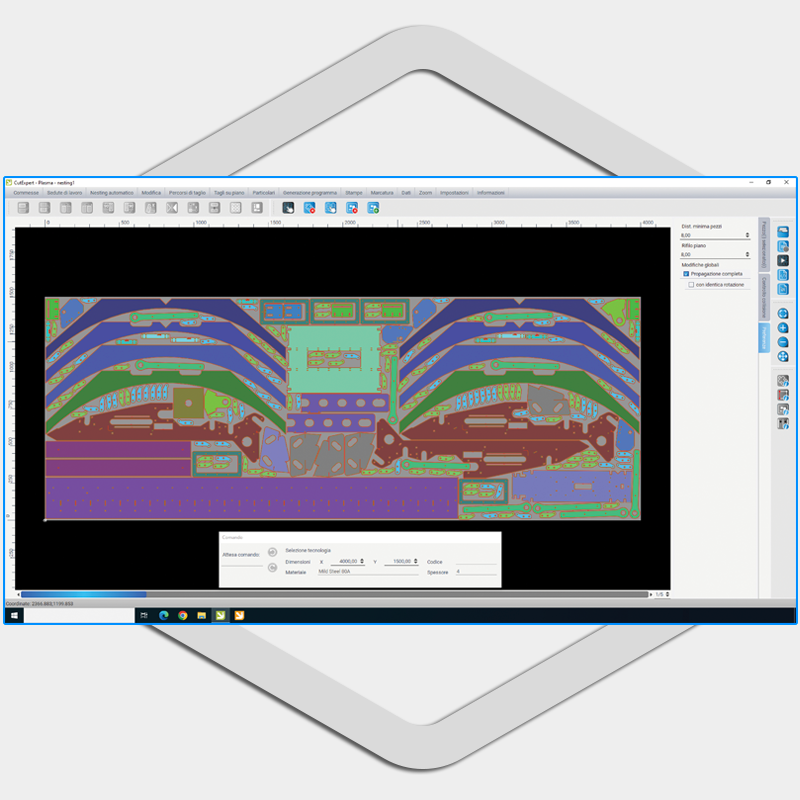

Automatic multi-level nesting with different materials/thicknesses

After an order has been completed it is possible to allocate the pieces through automatic nesting which manages an unlimited number of planes of different materials and thicknesses. It is possible to provide both the quantities and the format of the sheets on which to nest.

Simulation and Generation

The Cutexpert is able to manage more than 120 types of machines. Optimization can be simulated using times from the quoting engine. Just like when watching a movie, it can be started, slowed down, sped up, stopped. While the file execution is displayed, information such as slowdowns, height lock, flying cut or other are reported.

Mosaic: advanced automatic nesting

Mosaico is one of the best nesting systems on the market: in just a few seconds it is capable of positioning the pieces perfectly. It is able to choose the best rotation angle of each piece (the user can eventually force a rotation step). The user can decide a priority to give to the pieces. It is modern, fast and multithreaded nesting, it can insert pieces into the holes of other pieces and complete partially allocated plans (scrap management). Sheet metal requirements: Mosaico is able, given an order and the costs of each available sheet metal format, to choose the most convenient formats on which to insert the pieces.

Open files

With CutExpert it is possible to open DXF and DWG files up to the latest version of AutoCad, DSTV, MCAD, ECAD files (native Eurosoft format).

Saving files

Saving files in ECAD format, native Eurosoft. Saving files in DXF and DWG formats (R12, R13, R14, 2004, 2007, 2010, 2013, 2018-2023).

BOM management

Very useful for those who make compounds in series (e.g. refrigerators or ventilation ducts). It allows you to create a list of pieces to cut and recall it with a simple click.

Cutting on flat boundary

This component allows you to cut only the inside of a dxf. Very useful for those who want to cut only holes or split sheets of sheet metal. Ideal module for pipe cutters.

Joint cut

This is a feature that overlaps identical sides of parts. It can be either manual or automatic and has the advantage of decreasing lead time and scrap.

Print and quote management

Cutexpert has a module to manage the calculation of quotes. One or more printers can be configured on which to send tables and graphs that can be totally set during configuration. It is possible to enter the nominal speed for each type of route and manage parameters such as cost per kg of material and cost per hour. In addition, an XML file containing all the information associated with the parts contained in the plan can be produced during machine file generation. In this way it interfaces directly with Revolution 4.0 software. There are OpenOffice engine-based reports that produce user-editable ODT files and PDF files.

Automatic marking

Cutexpert has an automatic part marking module; chosen any TrueType font and font size, name, id, description and other fields can be printed. The position of the marking can be derived from the parametric part (assembly references) or is optimized to avoid any holes.

Command propagation

All commands in the CAM can be propagated to similar parts and/or paths.

Scrap management

Plans that are not completely filled can be archived and later re-used in subsequent nestings. A scrap database is present; each scrap can be associated with a code.

Fly cut

in complete harmony with the execution capabilities of the numerical control, it is possible to handle fly cut, with which paths containing inline profiles can be quickly made. The user can identify lines to be made in fly cut by simply pre-selecting these lines and applying this type of machining.

Undo & Redo

Undo Redo have been implemented for every command in the software, including features related to nesting management.Zoom commands are excluded from undo redo chains.

Microjunctions

Microjunctions can be entered, either manually or automatically, possibly with connections and outputs.

Attack and output management

Couplings and outlets can be added, either manually or automatically: the user chooses the type of coupling and outlet on a model part, then the software takes care of the automatic insertion, respecting the position of the insertion point. There is a database of attachments/outlets in the software, dependent on material, thickness and machining type.

Revolution 4.0

It is the intelligent software module created by Eurosoft that allows the Cutexpert to interact with various types of machines by retrieving all useful information for 4.0. It allows the Cutexpert to make summaries using actual cutting times.

Multi-level command stack

Multiple commands can be launched simultaneously with Cutexpert. This allows, for example, starting a command, zooming in to enlarge the work area, and then ending the started command. Without ever exiting and having to relaunch the initial command.

Manual modifications

Any point or length in the software can be entered directly by the user (for example, a point can be edited with this notation (xxx;yyyy) ).Calculations can be entered using operation symbols ( + - * / ) and parentheses.

Standard Cam Operations

The software allows you to move, rotate and mirror objects.You can change the direction of travel of a path. There are features for aligning and juxtaposing objects with each other. The user can also disable or enable individual paths or pieces: this allows paths to be excluded from generation for the machine. Objects can be copied, cut and pasted, even between different work planes, even between different instances of the software ( the user can start more than one Cutexpert at the same time ). There is a feature for measuring the distance between objects or between objects and the plane. An object placed on the plane can be quickly modified by calling up CAD (for example, changing the diameter of holes in a part).

Cut sorting

Cutexpert has an efficient cutting sorting engine. It recognizes inner and outer paths and automatically sorts them. However, the user can produce a cutting sorting based on the type of processing of the paths, considering individual objects or the whole plane. The user can also set up a manual cutting sorting.There is a general cutting sorting configuration table, with which one can choose whether to sort internal paths or external paths first, depending on the type of machining.

Minimum heating cutting sorting

Cutexpert succeeds in sorting the workings that minimizes the heating of the sheet metal.

Verification of profiles

There are tools for verifying imported profiles. In particular, it is possible to check for invalid entities and duplicate entities. It can be checked whether a profile is closed.

Collision check

It can be easily checked whether there are out-of-plane workpieces or overlapping workpieces, possibly considering or not the minimum distance and attachments/outlets. Movement of parts within the plane is controlled to avoid collisions.

Multi-language support

Cutexpert can switch from one language to another in one click.Currently Italian, English, German, French, Spanish and Hungarian are supported.New languages can be added upon request.

Cross cutting of scrap

It allows to disintegrate the scrap in the holes, avoiding the use of microjunctions and obtaining "clean" holes.

Multi machine management

By entering a single parameter in the job order, outputs can be generated for multiple machines.(e.g., sheet metal+coil with one output).

Rainproof (HVAC only)

Instantly handles ridge overlaps to prevent water infiltration into the part.

SIMPLICITY of use

Thanks to CutExpert® HVAC, the cutting technique becomes within the reach of anyone aiming for the perfection of the finished product, indiscriminately on any type of processing, whether it be aeraulic, insulation or suction.The software, with a renewed and even more intuitive design, uses a perfectly integrated cad and cam, thus allowing for maximum precision and space optimization.

1 > 2 > 3 > TO CUT

With only 3 steps it is possible to get straight to cutting a job order

Insert

1

Quickly import your drawings.You can enter all the items to be cut very easily by assigning them material, thickness and quantity. You can also extrapolate individual parts from a title block in which layers and colors are well defined to divide the various processes.

HVAC

A catalogue with over 180 BASIC SHAPES

Once the subject has been chosen from the default or customised catalogue, it is possible to keep all the configuration parameters under control from the edit window.it is possible to vary the dimensions, the type of overlap to be applied and the material to be used.thanks to the 3D visualisation, it is possible to have a view of the finished part in real time so as not to make mistakes.by configuring a single part, it is possible to create the output for each machine and for each type of machining (sheet metal, flanges, insulation).

AUTOMATIC OVERLAPS

In-depth knowledge on the subject, developed through years of direct experience in the HVAC industry, has allowed Eurosoft to add the option to automatically configure and use overrides to the software, so that the operator saves considerable time, with no margin for error.

OPTIMIZATION

Integrated Cam

Whether it is a straight or angled cut, overlapping or drilling, CutExpert® HVAC manages to achieve maximum results in extremely short time and without requiring operator intervention.

GENERATION

Export for more than 100 types of machines One click creates the file with all the instructions needed to move the machine to make the parts.

CARATTERISTIQUES

Brochure

Download the CutExpert V6 presentation brochure in PDF version

DEMO

Book an appointment with one of our technicians

Request informations

Click and get in touch with your personal assistant to get all the information on the product