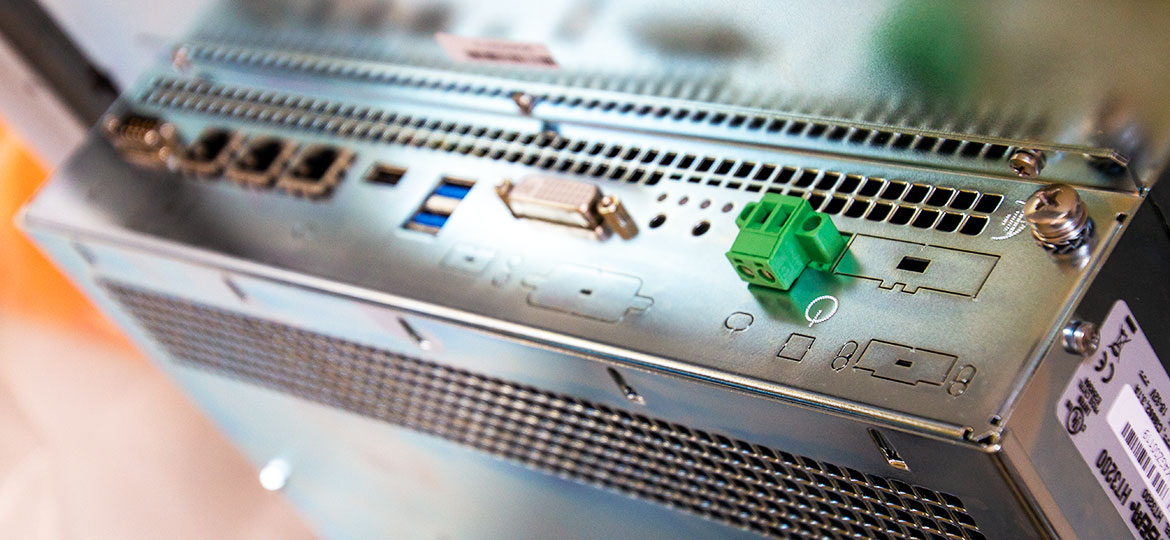

Panel PC

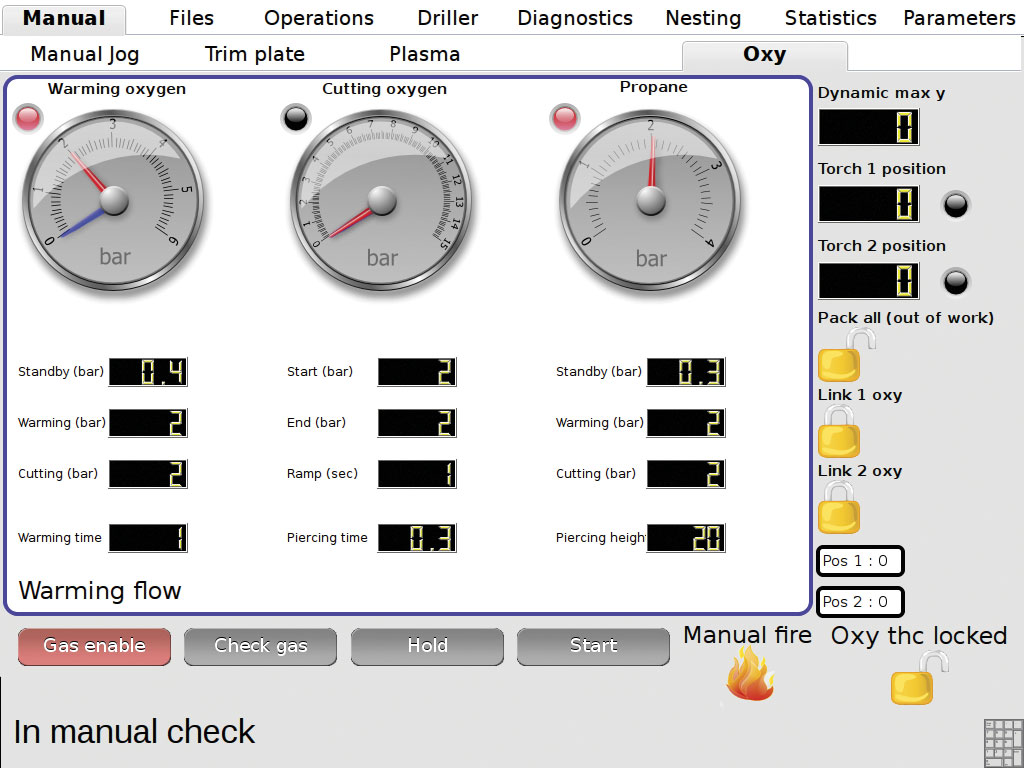

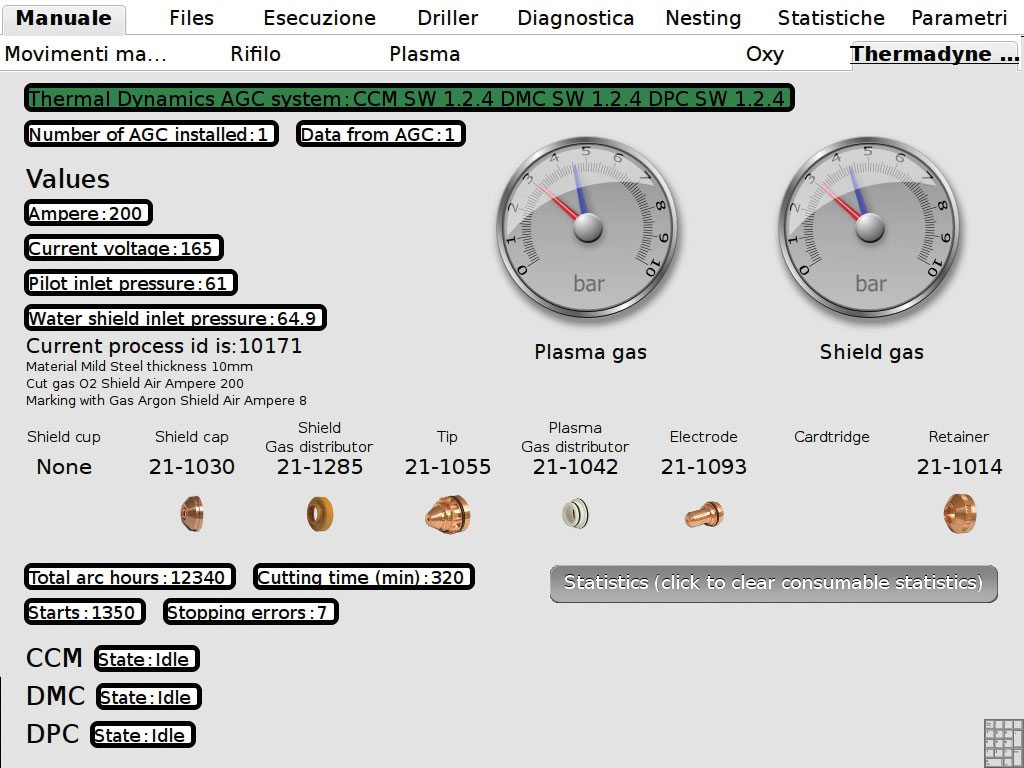

System input is via programs in ISO format. Instructions read from the ISO program are listed and clearly visible on the screen, but for normal use, it is sufficient to consider only the different cut planes and tracks (paths). Given the large number of predefined configurations, each of which is easily further customizable, the system is extremely flexible and can be adapted to all possible scenarios. Some existing configurations are illustrated in the following, and many others are possible. Integrated communication directly to the Plasma source, so that the ECP-1000 system displays real-time information about the cut process (gases, current, cooling system – every bit of information). This makes it unnecessary to install additional control panels available as expensive options for many common Plasma sources.

Key FEATURES

- Zero and rotation management

- Zero and rotation management

- ISO snap : Snap to track and restart – it suffices to move the torch near the point of restart, the current position will be projected on the nearest point of a track

- Complete freedom of moving the machine after putting the cutting program in pause, for any maintenance that could be necessary

- Immediate adjustment of every main cutting parameter: feed rate, arc voltage, piercing time and so on, with no delay change of the cutting process

- Shapes Library with many useful common 2D parts

- Internal database for cutting processes and raw material sizes

- Real-time recording of actual and programmed position of the motors during the execution, with easy display on the system panel.

- VPN (Virtual Private Network) based Desktop Sharing for remote assistance

- Integrated nesting function for immediate reuse of drawings available in Dxf/Dwg (Autocad TM) standard formats

- Recording data on sqlite database for online statistics (available on the controller) and offline (requirements Industry 4.0)